Understanding the Role of Auto Parts Manufacturers in the Industry

In the ever-evolving landscape of the automotive industry, auto parts manufacturers play a crucial role that is often overlooked. These manufacturers are not just suppliers; they are the backbone of the automotive supply chain, contributing significantly to both the quality and availability of vehicles. As the industry faces new challenges and opportunities, understanding the importance of these manufacturers is essential for anyone involved in the automotive sector.

The Importance of Auto Parts Manufacturers

In today’s fast-paced automotive market, the demand for high-quality auto parts is more significant than ever. Here are some key reasons why these manufacturers are so essential:

- Quality Assurance: Manufacturers ensure that the parts are built to meet strict standards, contributing to overall vehicle safety and performance.

- Innovation and Technology: They invest in research and development to innovate new parts and improve existing ones, keeping up with the latest technological advancements.

- Supply Chain Efficiency: Efficient manufacturers develop streamlined processes, ensuring parts are delivered on time and reducing downtime for automotive companies.

- Customization and Flexibility: Many manufacturers offer customized solutions to meet the specific needs of automotive companies, enhancing customer satisfaction.

The Challenges Faced by Auto Parts Manufacturers

While the role of auto parts manufacturers is vital, they also face several challenges that can impact their operations:

- Global Competition: The rise of globalization has led to increased competition from manufacturers around the world, putting pressure on quality and pricing.

- Regulatory Compliance: Navigating the maze of regulations, particularly in emissions and safety, can be daunting and costly.

- Technological Adaptation: Keeping up with the rapid pace of technological change, especially with the rise of electric vehicles and smart technologies, is a constant challenge.

- Supply Chain Disruptions: Events like natural disasters, trade wars, or pandemics can severely disrupt supply chains, affecting production and delivery.

Advancements in Auto Parts Manufacturing

Despite these challenges, the auto parts manufacturing sector is making significant advancements. These innovations are forging a path for more efficient and sustainable practices:

1. Lean Manufacturing Techniques

Many manufacturers are implementing lean manufacturing techniques to minimize waste and maximize efficiency. By focusing on value-added processes, manufacturers can reduce costs while maintaining high-quality output.

2. Automation and Robotics

The integration of automation and robotics into the manufacturing process has revolutionized the industry. Automated systems enhance precision, reduce labor costs, and significantly speed up production times.

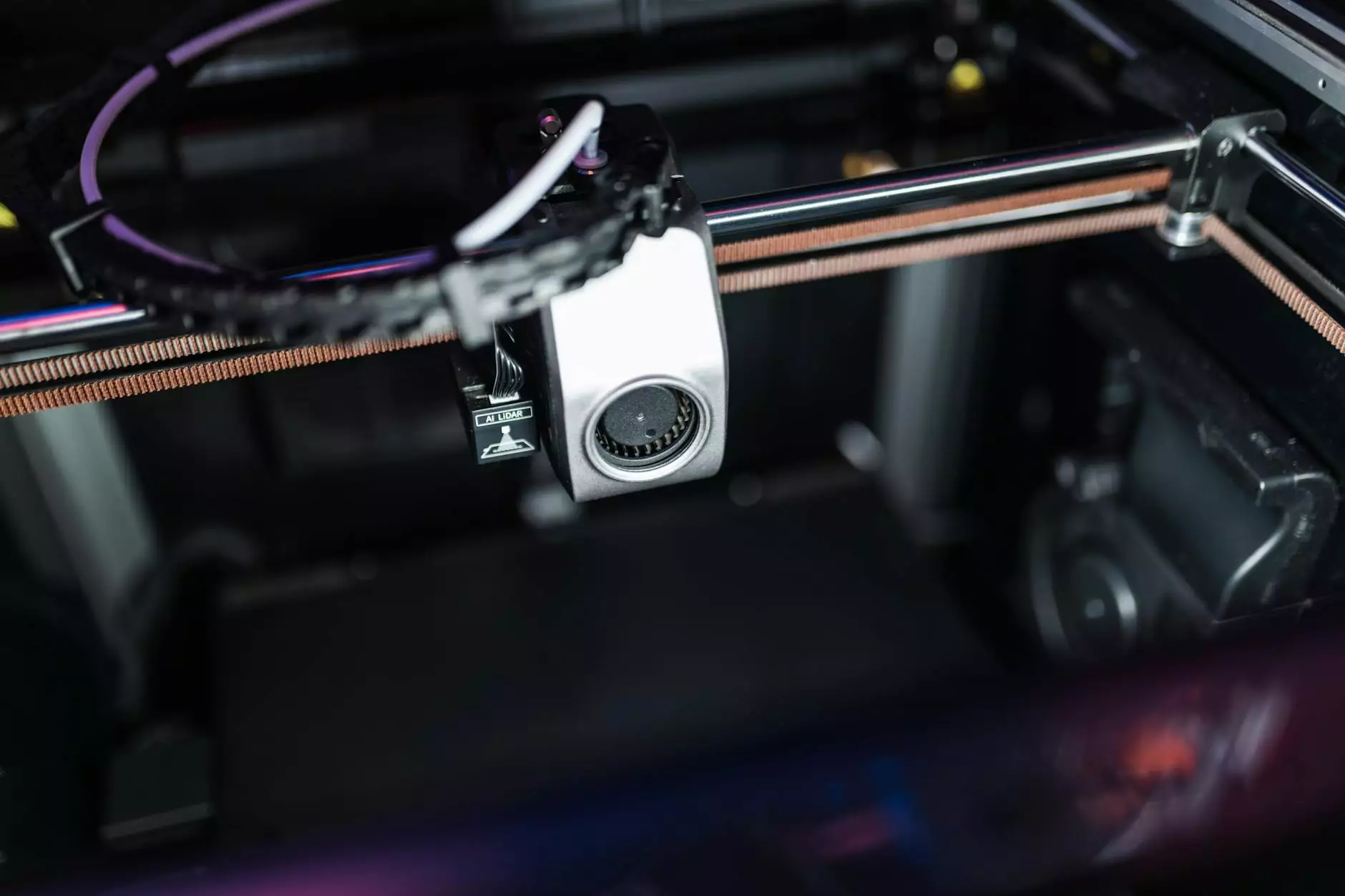

3. 3D Printing Technology

3D printing is enabling manufacturers to create prototypes and components much faster than traditional methods. This technology allows for rapid design iteration and customization, significantly enhancing the development process.

4. Sustainability Initiatives

With increasing awareness of environmental issues, many manufacturers are committing to sustainable practices. This includes using recyclable materials, reducing waste, and lowering carbon emissions throughout their operations.

The Future of Auto Parts Manufacturers

Looking ahead, the future of auto parts manufacturing is exciting. The following trends are expected to shape the industry:

- Electric and Hybrid Vehicles: As more manufacturers pivot towards electric vehicles, the demand for specialized auto parts that support these technologies will grow.

- Advanced Materials: The industry will see a shift towards lighter and stronger materials, improving vehicle efficiency and performance.

- Smart Parts: The integration of smart technology in auto parts is on the rise, leading to components that can communicate with vehicles and enhance user experience.

- Global Supply Chain Integration: Manufacturers are likely to forge stronger partnerships globally, focusing on developing more resilient supply chains that can weather disruptions.

Building Relationships in the Auto Parts Sector

Developing strong relationships within the auto parts sector is vital for manufacturers. Collaboration with suppliers, automotive companies, and other stakeholders can lead to improved materials, better design processes, and increased overall productivity. Manufacturers should focus on:

- Transparent Communication: Open lines of communication can ensure that all parties are aligned in their goals and expectations.

- Joint Ventures and Partnerships: Collaborating with other companies can lead to shared resources and knowledge, which can drive innovation.

- Feedback Mechanisms: Establishing systems for receiving constructive feedback from clients and partners can help manufacturers continuously improve their products and services.

Conclusion: The Indispensable Role of Auto Parts Manufacturers

In conclusion, auto parts manufacturers are essential players in the automotive industry. Their commitment to quality, innovation, and sustainability is vital for meeting the current and future demands of the market. As the automotive landscape continues to change, these manufacturers must adapt and evolve to remain competitive. Investing in technology, building strong relationships, and focusing on sustainability will be key to their success in the years to come. Understanding and supporting the role of these manufacturers ensures a robust automotive industry that benefits both consumers and manufacturers alike.

For more information on high-quality auto parts and supplies, visit us at imautoparts.com for comprehensive solutions tailored to your needs.